FERRET - Automatic, Hydraulic Leak Detection - A simple and reliable way of accurately locating leaks

The Ferret leak location system is an award winning device that delivers an innovative hydraulic solution for finding leaks in water pipes. The system significantly reduces the amount of time and number of excavations required to pinpoint and repair leaks, minimising disruption to customer's property.

The patented technology provides a fast and accurate method for finding even the smallest leaks on smooth bore service pipelines made of plastic, copper and lead. The system is designed for pipes with diameters from 10mm (3/8") up to 45mm (1 3/4").

If you undertake leak detection and repairs on small bore pipelines Ferret will deliver a cost effective solution.

Companies who have purchased Ferret have achieved returns on their investment in under three months

- No requirement for external power or gas means operating costs are low

- Eliminates cut and cap as leaks are pinpointed to within millimetres enabling spot repairs

- Quickly locates tiny leaks that make no noise eliminating problem jobs

- Reduces the number and size of excavations which saves time and materials

- Operated by repair contractors for a more streamlined find and fix process

- Minimises disruption to private property reducing impact on customers

Key Benefits

- Effective in plastic, copper and lead pipes

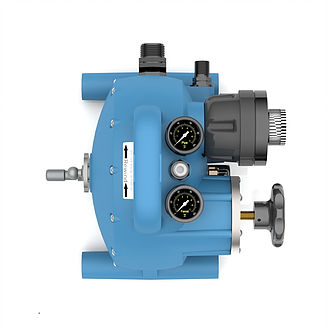

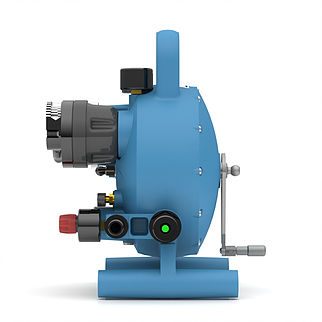

- Robust Head design with operating pressure from 1 to 5 Bar (72.5 PSI)

- Interchangeable Heads for locating leaks in pipes with internal diameters from 3/8" to 1 3/4" (10mm to 45mm)

- Heads pass easily through most types of joints and fittings

- 165 ft leak location survey from each entry point

- In-built high resolution flow sensor that quantifies leaks from 0.002 gal/min (0.13 gal/hr)

- Simple push button operation, competent use requires minimal training

- In-built line and end tracing features

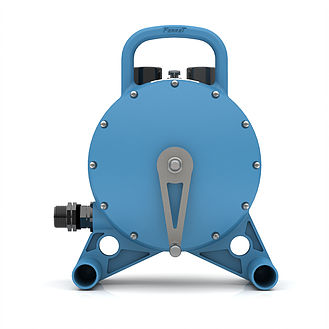

- Portable device weighing less than 23 lbs

Technology

The Ferret is an in-pipe tethered device that uses an innovative hydraulic process to accurately locate leaks, which makes it very effective in plastic pipes.

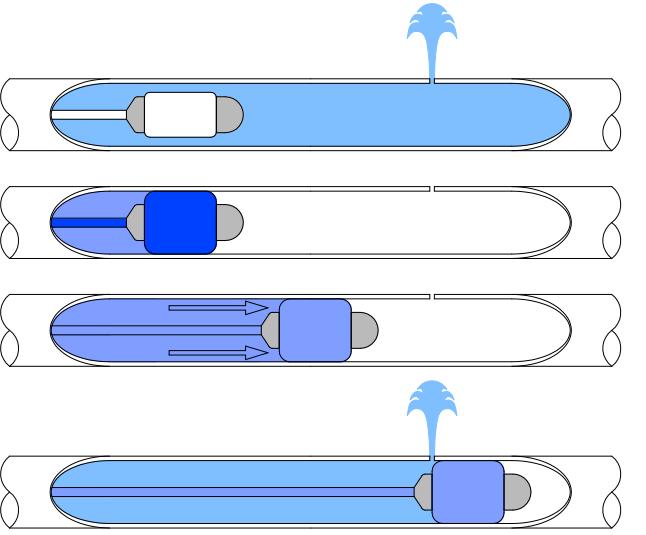

The system comprises of a loose fitting plug (the Head) that is introduced into the pipeline via an existing access point such as a meter or valve pit, or directly into the exposed pipeline. The system is powered by the water pressure in the pipe. The Head is inflatable and acts like a valve, which can be moved along the pipe to determine the exact position of the leak. The valve has three states – OPEN, CLOSED and MOVING.

OPEN – When the pressure in the Head is lower than in the pipe the water gets past it.

CLOSED – The Head is inflated with water until the pressure inside it is higher than in the pipe. The Head is now blocking the pipe.

MOVING – When the pressure in the Head is adjusted so that it is the same as the pressure in the pipe, the Head is pushed forwards towards the leak by the pressure in the pipe. When the Head passes the leak some of the pressure that is pushing it is lost through the hole in the pipe. The pressure in the Head is higher now than the pressure in the pipe so it stops moving.